NTC thermistors and PTC thermistors are two common types of electronic devices used for temperature sensing and control. These specialized resistors offer distinct characteristics and applications, making them essential components in various industries. This article will explore the differences between NTC thermistors, which exhibit a negative temperature coefficient, and PTC thermistors, which exhibit a positive temperature coefficient, highlighting their unique properties and uses in temperature-related applications.

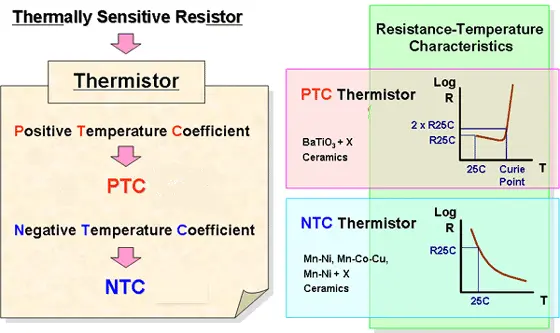

Part 1. What is a thermistor?

A thermistor is a particular type of sensor that measures temperature. It consists of semiconductor materials such as metal oxides or ceramics. When the temperature changes, the thermistor’s electrical resistance changes too. This helps us know how hot or cold something is.

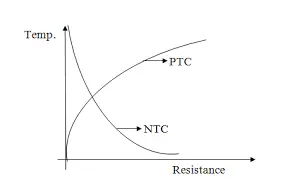

There are two main types of thermistors: positive temperature coefficient (PTC) and negative temperature coefficient (NTC). PTC thermistors get more resistant as they get hotter, while NTC thermistors get less resistant as they get hotter.

Part 2. Why do lithium batteries need thermistors?

Temperature Monitoring

Thermistors help monitor the temperature of lithium batteries. It can be dangerous if a battery gets too hot or cold. High temperatures can lead to overheating and even explosions in extreme cases. Freezing temperatures can make the battery less efficient and cause damage over time. Thermistors monitor the battery’s temperature and alert the device to take action if it’s too hot or cold.

Overheat Protection

When lithium batteries are being used or charged, they can sometimes generate heat. Mismanagement of this heat can lead to problems. Thermistors help prevent overheating by monitoring the temperature and signaling the device to stop charging or reduce power if necessary. This protects the battery from damage and ensures it lasts longer.

Battery Life Optimization

By keeping the temperature in check, thermistors help prolong the life of lithium batteries. Excessive heat can degrade the battery, reducing its capacity and lifespan. Thermistors help optimize the battery’s performance and longevity by maintaining a safe temperature range.

Part 3. NTC Thermistors

Characteristics

- Temperature Sensitivity: NTC thermistors exhibit a high sensitivity to temperature changes, making them ideal for accurate temperature measurements.

- Resistance-Temperature Relationship: As the temperature increases, the resistance of NTC thermistors decreases. This negative temperature coefficient behavior is essential for their temperature sensing capabilities.

- Nonlinear Response: NTC thermistors have a nonlinear relationship between resistance and temperature. The resistance change is most significant at lower temperatures, allowing for precise measurements in a specific temperature range.

Working Principle

NTC thermistors operate based on the behavior of certain semiconductor materials. These materials exhibit properties where the number of charge carriers increases as the temperature rises. Consequently, the increased thermal energy enhances the conductivity and decreases the resistance of NTC thermistors. This characteristic enables them to sense and measure temperature variations in a given environment accurately.

Applications

- Temperature Measurement and Control: People commonly use NTC thermistors in temperature sensing and control applications, such as integrating them into thermostats for HVAC systems, refrigerators, and water heaters.

- Overheat Protection: They are utilized in electronic devices and systems to prevent overheating by monitoring temperature levels and triggering safety mechanisms if temperatures exceed safe limits.

- Battery Management: NTC thermistors are integrated into battery packs to monitor the temperature of lithium-ion batteries, ensuring safe charging and discharging operations.

- Automotive Systems: NTC thermistors are employed in automotive applications to monitor engine temperature, coolant temperature, and cabin temperature control.

- Medical Devices: They find use in equipment for body temperature monitoring, including thermometers and incubators.

- Industrial Process Control: NTC thermistors play a crucial role in industrial temperature sensing and control processes, ensuring optimal operation and product quality.

Part 4. PTC Thermistors

Characteristics

- Positive Temperature Coefficient: PTC thermistors exhibit an increase in resistance as the temperature rises beyond a specific temperature threshold.

- Sharp Resistance Transition: PTC thermistors sharply increase resistance once the temperature exceeds the threshold, resulting in nearly constant resistance above that point.

- Limited Sensitivity: PTC thermistors offer less sensitivity to temperature changes than NTC thermistors.

- Self-Resetting: These thermistors can self-reset once the temperature drops below the threshold, allowing them to protect against overcurrent or overtemperature conditions.

Working Principle

The working principle of PTC thermistors relies on the behavior of ferroelectric ceramics. As the temperature increases, these ceramics undergo a phase transition, leading to a sudden increase in resistance. This behavior allows PTC thermistors to act as self-resetting fuses or components that limit current flow during overcurrent or overtemperature conditions.

Applications

- Temperature Sensing and Control: People commonly use PTC thermistors in temperature sensing and control applications, such as integrating them into thermostats for household appliances like heaters and air conditioners.

- Overcurrent Protection: They are employed in electronic circuits to provide overcurrent protection, where the increase in temperature triggers a self-limiting effect, reducing current flow to prevent damage to components.

- Motor Starting Devices: PTC thermistors serve as motor starting devices in various equipment, such as refrigerators and air compressors, by providing a high initial resistance that decreases as the engine starts, ensuring smooth operation.

- Inrush Current Limiting: People utilize PTC thermistors to limit inrush currents in power supplies and electronic devices during startup, preventing damage to components and enhancing system reliability.

- Battery Protection: They find applications in battery packs to protect against overcharging and over-discharging by controlling the charging and discharging currents based on temperature changes.

- Temperature Compensation: PTC thermistors are used for temperature compensation in electronic circuits, ensuring stable performance of components over a wide temperature range.

Part 5. Differences between NTC and PTC thermistors

1. Resistance-Temperature Relationship:

- NTC thermistors exhibit a negative temperature coefficient, meaning their resistance decreases as the temperature rises.

- PTC thermistors exhibit a positive temperature coefficient, causing their resistance to increase as the temperature rises beyond a specific threshold.

2. Sensitivity to Temperature Changes:

- NTC thermistors are highly sensitive to temperature changes, allowing for precise temperature measurements.

- PTC thermistors offer limited sensitivity to temperature changes compared to NTC thermistors.

3. Resistance Transition Behavior:

- The resistance of NTC thermistors changes nonlinearly with temperature variations, with the most significant resistance change occurring at lower temperatures.

- PTC thermistors exhibit a sharp resistance transition once the temperature exceeds a specific threshold. Above this threshold, their resistance remains nearly constant.

4. Self-Resetting Capability:

- NTC thermistors do not possess self-resetting capabilities. Their resistance continuously varies with temperature changes.

- PTC thermistors have self-resetting capabilities. Their resistance decreases when the temperature drops below the threshold, allowing them to reset automatically.

5. Applications:

- People commonly use NTC thermistors as temperature sensors, temperature compensation devices, heating elements, and temperature monitoring in various industries such as automotive, HVAC, and medical.

- People often use PTC thermistors for overcurrent protection, motor starting devices, temperature-controlled switches, overtemperature protection, and automated heating elements in consumer electronics and appliances.

Part 6. Conclusion

NTC and PTC thermistors are two distinct types with contrasting characteristics and applications. NTC thermistors exhibit a negative temperature coefficient, offering high sensitivity and precise temperature measurements. In contrast, PTC thermistors have a positive temperature coefficient and provide self-resetting capabilities for overcurrent and overtemperature protection. Understanding the differences between these thermistors allows for informed selection and optimal utilization in various temperature-related applications.

Related Tags:

More Articles

Overview of Deep Cycle Lithium Battery

In this article, we explore the life, voltage, capacity, and charging considerations of deep cycle lithium batteries.

How Long do Lithium Batteries Last?

How long do lithium batteries last? we will explore the factors that influence the lifespan of lithium batteries and provide insights into their longevity.

How to Choose the Best LiFePO4 Battery?

Choose LiFePO4 batteries for superior performance, safety, and versatility in EVs, UPS, and backup power. This guide helps you make informed decisions.

Get 12v Lithium Car Battery As a Power Source for the Ride

Make the right choice for your vehicle's battery needs by installing a 12 volt lithium car battery. You will enjoy maintenance-free longevity with this change.

Everything About A Small Lithium Ion Battery

Discover the features, uses & future potential of a small lithium ion battery. A compact and tiny powerhouse ideal for smartphones, wearables, drones & more.